Who are we

Ravebo is a leading company in the field of liquid-gas separation and liquid-gas integration for several decades. These competences are applied in the widest variety of industries for new installations but also to optimize processes and in particular, separating droplets from a gas stream. In order to provide our customers with the best possible knowledge and support in this, we have all the disciplines at our disposal to be able to carry out these applications entirely in-house.

Ravebo is a leading company in the field of liquid-gas separation and liquid-gas integration for several decades. These competences are applied in the widest variety of industries for new installations but also to optimize processes and in particular, separating droplets from a gas stream. In order to provide our customers with the best possible knowledge and support in this, we have all the disciplines at our disposal to be able to carry out these applications entirely in-house.

Ravebo Brielle develops, supplies and installs complete high end droplet separators and separator systems for every industrial application. With a highly skilled team of engineers and installation technicians we will get to work on each individual application. The systems are visualized in advance by means of Autodesk Inventor software in which the whole is implemented in 3D presentations in the customer's production installation. This method has the enormous advantages that the lead time and costs are small and the end result is already visible at the quotation stage.

- Radial separators

- Cyclones

- Vane type separators

- Primary separation

- Secondary separation

- Wire woven demisters

Get in touch with us

Droplet Separator

In many companies, liquids or gases or both are needed for the course of certain production processes. In cases where liquid and gas come into contact with each other during the process, a separation of liquid and gas is required at least at the end of the process or process phase. If this separation is not carried out completely, the whole process can be unprofitable, or if the gas flow is emitted into the atmosphere, the environment can be unnecessarily affected by the liquid being transported. Apart from special cases, the liquid from the gas stream is usually separated by mechanically acting separators which function on the basis of mass inertion. For most applications, radial separators, cyclones, vane type separators and wire mesh demisters are used. Important criteria for assessing the performance of a droplet separator are separation rate, limit droplet size and pressure loss. The limit droplet size of a separator are those droplets that can be completely secreted; all droplets smaller than the limit droplet size of a separator are separated only for a certain percentage. We call this the fractional separation rate.

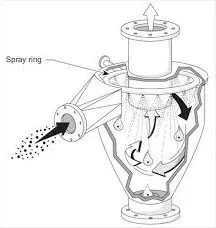

(Droplet Separators)Radial separators

The radial separator, as a variant of a axial cyclone without current reversal, is a swirl type separator is a special design of the cyclones. It is often used under harsh operating conditions where large quantities of liquid must be separated in the form of coarse droplets, whereby the gas flow can also contain solids. The degree of separation of a spin vane separator is usually 98 to 99 %, for a limit droplet size of on average about 50 to 100 microns. The pressure losses of radial separators are usually 6 to 15 mbar. In the separator, the incoming exhaust gas is cleaned by deposition of droplets. For this phase separation, the gas flow is initially accelerated by a fixed swirl generator in the circumferential direction. Curved blades prevent inlet losses and flow deviations. A stable and trouble-free rotational current is formed in the spiral tube behind it. Due to the centrifugal force, the droplets are hurled outwards to the wall and collected there.

The radial separator, as a variant of a axial cyclone without current reversal, is a swirl type separator is a special design of the cyclones. It is often used under harsh operating conditions where large quantities of liquid must be separated in the form of coarse droplets, whereby the gas flow can also contain solids. The degree of separation of a spin vane separator is usually 98 to 99 %, for a limit droplet size of on average about 50 to 100 microns. The pressure losses of radial separators are usually 6 to 15 mbar. In the separator, the incoming exhaust gas is cleaned by deposition of droplets. For this phase separation, the gas flow is initially accelerated by a fixed swirl generator in the circumferential direction. Curved blades prevent inlet losses and flow deviations. A stable and trouble-free rotational current is formed in the spiral tube behind it. Due to the centrifugal force, the droplets are hurled outwards to the wall and collected there.

The drops are not affected by the dragging of the gas. The liquid does not run up in the direction of the gas, but downwards. This effect is achieved by the special profiling and arrangement of the "spiral", which is formed downwards in the direction of the gas. At the level of the vertebral body, the fluid is collected and drained. At the same time, the design also promotes a cleaning of the inside of the spiral pipe.

In critical applications, deposits in the separator and on the blades of the swirl body can be avoided with additional rinsing systems. The use of rinsing systems is possible during operation without creating new droplets in the purified gas. The radial separators are specifically dimensioned for larger liquid loads.

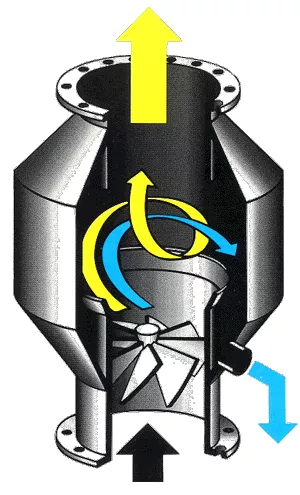

Cyclones

Due to occurring centrifugal force, the droplets are hurled to the outer wall where they coalesce and form a liquid film which then runs down along the wall and can be collected. Cyclones are used in similar cases as radial separators used but unlike these, they can reach smaller limit droplet sizes with higher pressure losses. The degree of separation of a cyclone is about 98 to 99% for a limit droplet size of on average about 30 to 50 microns with pressure losses of about 10 to 20 mbar. The limit droplet size decreases as the pressure loss over the cyclone increases. In addition, for the separation of droplets, a large cyclone will have a lower efficiency compared to a small cyclone

Due to occurring centrifugal force, the droplets are hurled to the outer wall where they coalesce and form a liquid film which then runs down along the wall and can be collected. Cyclones are used in similar cases as radial separators used but unlike these, they can reach smaller limit droplet sizes with higher pressure losses. The degree of separation of a cyclone is about 98 to 99% for a limit droplet size of on average about 30 to 50 microns with pressure losses of about 10 to 20 mbar. The limit droplet size decreases as the pressure loss over the cyclone increases. In addition, for the separation of droplets, a large cyclone will have a lower efficiency compared to a small cyclone

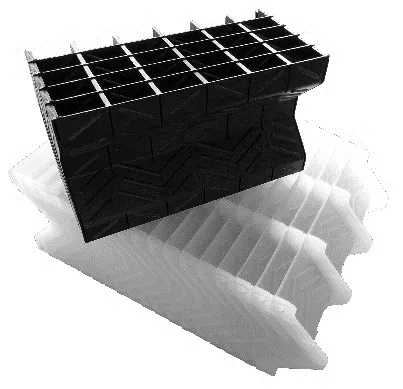

Vane type separators

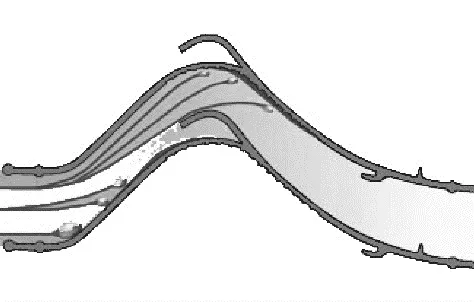

Vane type separators normally consist of parallel profiles. The shape and length (in flow direction) determine the efficiency of the separator. With a greater curvature and more complex shape of the profile, in particular, the smaller droplets, due to their mass inertion, will be able to be separated from a straighter, simpler profile. If a finer droplet spectrum is required for the separation of liquid droplets from gas streams, vane type separators are usually used for both vertical and horizontal gas streams. The greater risk of dirt deposition compared to radial separators and cyclones is manageable when flushing the separators discontinuously or continuously. In extreme cases, the use of a multistage system is required, in which the first separation phase is rinsed particularly intensively. Vane type separators achieve a high separation rate of 99.9%. Vertically and horizontally flown vane type separators differ mainly from each other due to pressure loss, limit droplet size and permissible gas velocity. While the boundary droplets of a vertically flowed separator amount to about 40 microns, a horizontally flowing vane type separator can reach a limit droplet size of 10 to 20 microns. In the vertically flowed vane type separator, the vanes are tilted horizontally or at a small angle to the horizontal plane. The liquid must run down in the opposite direction of the gas. A vertically inflowed separator profile shall be designed in such a way that low-speed zones can be found on the profiles, in which mainly deposited liquid droplets can accumulate (agglomeration) without interacting with the gas flow above them. These zones are also used for the proper removal of the liquid droplets from the lamella separator.

Vane type separators normally consist of parallel profiles. The shape and length (in flow direction) determine the efficiency of the separator. With a greater curvature and more complex shape of the profile, in particular, the smaller droplets, due to their mass inertion, will be able to be separated from a straighter, simpler profile. If a finer droplet spectrum is required for the separation of liquid droplets from gas streams, vane type separators are usually used for both vertical and horizontal gas streams. The greater risk of dirt deposition compared to radial separators and cyclones is manageable when flushing the separators discontinuously or continuously. In extreme cases, the use of a multistage system is required, in which the first separation phase is rinsed particularly intensively. Vane type separators achieve a high separation rate of 99.9%. Vertically and horizontally flown vane type separators differ mainly from each other due to pressure loss, limit droplet size and permissible gas velocity. While the boundary droplets of a vertically flowed separator amount to about 40 microns, a horizontally flowing vane type separator can reach a limit droplet size of 10 to 20 microns. In the vertically flowed vane type separator, the vanes are tilted horizontally or at a small angle to the horizontal plane. The liquid must run down in the opposite direction of the gas. A vertically inflowed separator profile shall be designed in such a way that low-speed zones can be found on the profiles, in which mainly deposited liquid droplets can accumulate (agglomeration) without interacting with the gas flow above them. These zones are also used for the proper removal of the liquid droplets from the lamella separator.

Depending on the profiling and design of the vanes, these tasks are solved in different ways. Since the liquid is discharged against the gas flow, the liquid droplets to be drained must be forced into a downward motion, whereby they must be significantly larger than the upwardly lined droplets of the gas. Droplets smaller than the floating droplet are carried again and burden the system unnecessarily. For this reason, there are droplet separators for vertical flow with different liquid dispersions. Horizontally flown vane separators have different design features than vertical systems for secondary separation. In the horizontally flowed vane type separators, the vanes are perpendicular to the gas direction, so that the liquid runs down as a result of gravity. By creating low-flow zones in front of, in and behind the phase separation chambers, it is ensured that the liquid droplets can flow away without coming into contact with the gas flow again. The fact that gravity is used for draining the liquid leads to high-performance separators. Depending on the design, flow rates of up to 10 m/s are allowed. The most favorable design of the profiles cause low pressure losses. Tailored to the process requirements, vane profiles with single or multiple deflections can be applied. The function of the vane type separators is based on the fundamental physical law of mass inertion. The degree of separation is mainly determined by two processes: primary and secondary separation.

(Knock out drums)Primary separation

A gas stream loaded with droplets is passed through a framework consisting of curved and profiled vanes. In the deflection between the vanes, the liquid droplets that are carried into the gas stream on the basis of mass inertion are removed. These forces cause the trajectory of the droplets to deviate from the original gas flow. The geometry of the deflection, the gas and liquid parameters, size of the droplets and load of the droplets now determine whether a liquid droplet passes through the deflection or comes into contact with the profile wall of the vanes. Those droplets that come into contact with the separator profile for 100% under the certain conditions and form a liquid film there, are considered as boundary droplets. Drops with a diameter greater than or equal to the limit droplet are 100% separated. The droplets with a diameter smaller than the boundary droplets are partly separated. This part can be considered as a fractional separation rate. It can be used to assess the separation performance of a system.

A gas stream loaded with droplets is passed through a framework consisting of curved and profiled vanes. In the deflection between the vanes, the liquid droplets that are carried into the gas stream on the basis of mass inertion are removed. These forces cause the trajectory of the droplets to deviate from the original gas flow. The geometry of the deflection, the gas and liquid parameters, size of the droplets and load of the droplets now determine whether a liquid droplet passes through the deflection or comes into contact with the profile wall of the vanes. Those droplets that come into contact with the separator profile for 100% under the certain conditions and form a liquid film there, are considered as boundary droplets. Drops with a diameter greater than or equal to the limit droplet are 100% separated. The droplets with a diameter smaller than the boundary droplets are partly separated. This part can be considered as a fractional separation rate. It can be used to assess the separation performance of a system.

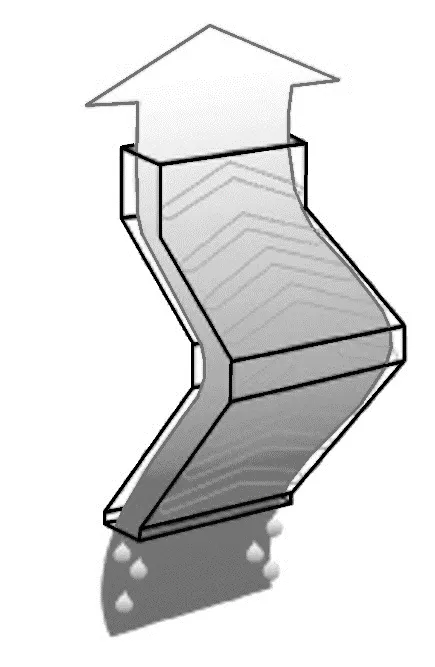

Secondary separation

The lamella shape and the design of the vanes ensure that the liquid film that forms on the lamella is drained completely out of the gas stream as a result of the primary separation. For this purpose, specially shaped discharge profiles are provided on the vanes. Separation systems, which have been specially developed for low pressure losses, work with guide grooves instead of with applied discharge profiles. Depending on the application, the discharge profiles are different in shape and size. In addition to the number of deflections, the shape of the discharge profiles has a major influence on the pressure loss of the separation system.

The lamella shape and the design of the vanes ensure that the liquid film that forms on the lamella is drained completely out of the gas stream as a result of the primary separation. For this purpose, specially shaped discharge profiles are provided on the vanes. Separation systems, which have been specially developed for low pressure losses, work with guide grooves instead of with applied discharge profiles. Depending on the application, the discharge profiles are different in shape and size. In addition to the number of deflections, the shape of the discharge profiles has a major influence on the pressure loss of the separation system.

Wire mesh demisters

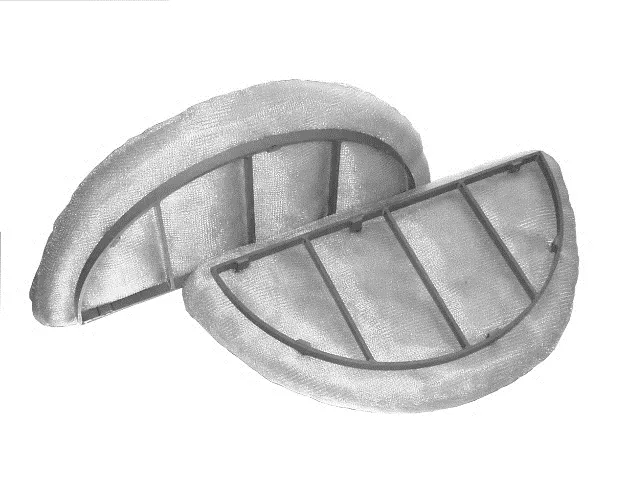

The operation of a wire mesh demister, as with a vane type separator, rests on the basis of mass inertion. If the diameter of the liquid droplets to be separated should be significantly smaller than 10 microns, a wire mesh demister can be used. A wire mesh demister is made up of thin thread which is "knitted around" in a three-dimensional model into a mat. This demister mat can be made in almost any desired shape so that the demister can be used in almost any vertically flown application. For small(er) diameters, the separator often consists of a part; for larger surfaces, the separator is composed of several parts, often because of the fact that the demister must be able to be removed via a manhole. The composition of the demister mat determines the efficiency of the demister in which a thin wire with the smallest possible distance from each other is suitable for separating the smallest droplets. Rinsing a wire mesh demister is very difficult, so its use is limited to liquids that do not cause dirt deposition. For this reason, in many cases it is not possible to use a wire mesh demister.

The operation of a wire mesh demister, as with a vane type separator, rests on the basis of mass inertion. If the diameter of the liquid droplets to be separated should be significantly smaller than 10 microns, a wire mesh demister can be used. A wire mesh demister is made up of thin thread which is "knitted around" in a three-dimensional model into a mat. This demister mat can be made in almost any desired shape so that the demister can be used in almost any vertically flown application. For small(er) diameters, the separator often consists of a part; for larger surfaces, the separator is composed of several parts, often because of the fact that the demister must be able to be removed via a manhole. The composition of the demister mat determines the efficiency of the demister in which a thin wire with the smallest possible distance from each other is suitable for separating the smallest droplets. Rinsing a wire mesh demister is very difficult, so its use is limited to liquids that do not cause dirt deposition. For this reason, in many cases it is not possible to use a wire mesh demister.

With a wire mesh demister, separation grades of 99.9% for limit droplet sizes from 5 to 20 microns are very common. However, in contrast to vane type separators for vertical flow, considerable pressure losses between 1.5 and 4 mbar must be taken into account, whereby this is also strongly depending on the liquid load of the gas. Due to the risk of dirt deposition and therefore clogging the package, it is obvious that these separators can only be used as a fine separator. During the separation process, the drops pass through the filter mat, collide with the wire surface due to their moment of inertia, agglomerate at the nodes of the wires and fall back like larger droplets. The separation performance, which is affected by the free volume and the specific wire surface of the mat, increases with an increasing gas rate. However, the maximum speed should not be exceeded because of the flooding that then occurs, that is, the dragging of drops. The limit droplet size for a 99.9% fractional separation rate is in the range of 5 - 10 microns for the different standard versions. Due to special constructions, such a deposit is possible with an appropriate design up to a size of 3 microns. The wire mesh demisters are knitted from thin threads in different mesh sizes, with the thread diameters usually varying between 0.1 mm and 0.5 mm. Depending on the type, the specific surfaces vary from about 100 m2/m3 to about 1,100 m2/m3.

To support the demister mats, specially designed support and/or cover grids are usually supplied, which are designed in such a way that the free flow surface is about 90%. When installing the wire mesh demister, care must be taken to ensure that the demister mat fits snugly to the column wall so that false air cannot escape. The mat height of the wire mesh demister is 100 to 150 mm for most applications. If the gas flow contains very fine droplets, such as those caused by condensation, a significantly larger mat height or a multi-layer structure may be required.

The fundamental considerations lead directly to procedures for sizing a wire mesh demister or a vane type separator in terms of flow surface, in order to process the throughput for a particular application. The most important variable is the gas velocity. In a certain application, a droplet separator has an optimal operating range. At speeds above this range, performance is hampered by entrainment, accompanied by flooding for all droplets, except for the lightest loads with mist. As the velocity decreases to the optimal range, the droplet secretion efficiency decreases more strongly for smaller droplets than for larger ones. At some point, the efficiency for drops at the lower end of the spectrum has dropped to an unacceptable level. This is then the lower limit of the velocity range.,/p>

A particular formula is widely used when sizing a wire mesh demister or vane separator for a particular flow rate. It generalizes the characteristics that are normally expressed (mainly with the exception of the low side of the range of action) from the essence of air and water to other gases and liquids. The Souders-Brown equation, has long been the usual tool for determining the maximum permissible vapor velocity in a packed vapor-liquid column.

(M. Souders and G. G. Brown, "Design of fractionating Columns. I. Entrainment and Capacity," Industrial & Engineering Chemistry, Volume 26 [1934], Pages 98-103.)

The equation is according to Newton's law for the final velocity of falling spheres. The version of the Souders-Brown equation is often used for droplet separators and sets a variable K called the vapor pressure factor; also known as the system load factor, Souders-Brown speed, or K factor as follows:

K=VG√((ρL- ρG)/ρG)K = vapour load factor (Souders-Brown speed)

VG = gas velocity

ρL = liquid density in the same magnitude as ρG

ρG = gas density in the same magnitude as ρL

The K-factor can be considered as an effective gas velocity for the purpose of expressing the throughput limit, adapted for the influences of liquid and gas density. This parameter makes it possible to determine the size for droplet separators in gas-liquid systems that are usually used for air and water on the basis of collected data.

Finally, the design K factors for both horizontal and vertical separators apply only to low to moderate liquid fills up to about 0.1% liquid in volume. For a speed of 3 m/s, this corresponds to about 0.5 l/min.m2. For higher liquid charge, K-factor must be adjusted. Lamella separators are less sensitive to the effects of the liquid load on capacity.

Vane type separators vs wire mesh demisters

1. High speed

Because they are less sensitive to entrainment and flooding than wire mesh demisters, loads can handle at speeds that are 30 to 40 percent higher A higher speed helps close the efficiency gap with wire mesh demisters;

2. High liquid load

Vane type separators typically process loads that can be about 5 to 10 times larger than wire mesh demisters (up to 500 l/m2.min versus 50 l/m2 for wire mesh demisters);

3. Pollution and clogging

Solid particles and debris that would get stuck in a wire mesh demister, which will eventually lead to premature replacement or cleaning, pass through the much larger openings of a vane separator. In applications subject to accumulation of deposits, much longer intervals are possible without cleaning and can be cleaned much easier than wire mesh demisters;

4. Longer tool life

The thickness of the vanes gives them a significantly longer service life than wire mesh demisters with the same corrosion rate. In a certain aggressive conditions, a profile made of sheet metal will last much longer than a wire mesh demister made of the same alloy;

5. Low pressure loss

The relative open construction of a vane type separator gives them an edge over a wire mesh demister in applications where a few inches of water column can be crucial;

6. High viscosity

There are a few applications in which a high viscosity hinders the liquid drainage so severely that a wire mesh demister would flood already at very low speeds and liquid loads. Vane type separators can handle much higher viscosities.

7. Robust construction

When properly secured in a frame or a locking structure, a vane type separator is well resistant to violent gas spikes and slurry-like liquids that would deform or irreparably damage even the most highly constructed wire mesh demister;

8. Foam accommodation

Due to liquid agitation in wire mesh demisters, these are generally not recommended in applications that are subject to foaming. Vane type separators, on the other hand, not only drain without foaming, but can actually prevent foaming. In view of points 3, 4 and 7 above, the vane separators are particularly well applicable in applications that require high reliability over longer periods without maintenance or replacement.

9. Separation efficiency

A wire mesh demister is able to separate much smaller fractions compared to a vane type separator.